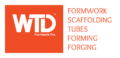

Cuplock

SPECIFICATION

Main Features:

- Node Locking: Unique locking mechanism using two cups, allowing four horizontal ledgers to connect to vertical standards at 500 mm intervals.

- Quick Assembly: Simple design requiring only a hammer and spirit level for rapid setup.

- Durability: Galvanized for corrosion resistance and long life.

- Safety Accessories: Guardrails, mesh panels, ladder and stair access, and overhead protection components for enhanced safety.

- Compact Design: Lightweight and compact for easy handling and storage.

- Proven Track Record: Reliable performance in various construction applications.

Cuplock Falsework: Commonly used for shoring and supporting concrete slabs efficiently with reduced labor.

Cuplock System Components:

- Standards: Available in lengths from 1000 mm to 3000 mm; made from 48.3 mm O.D. tube with welded lower cups.

- Ledgers: Horizontal members in various lengths; made from 48.3 mm O.D. tube.

- Transoms: Intermediate supports in different sizes; also made from 48.3 mm O.D. tube.

- Jacks: Includes Universal Jacks, Adjustable Base Jacks, and U Jacks for fine adjustments, available in both hollow and solid types.

- Accessories: Spigots for vertical connections, Base Plates, Steel Planks for platforms, and Beam Brackets for load transfer to standards.

Technical Specifications:

- Standards: 48.3 mm O.D. tube; available with open or welded spigot ends. Load capacity varies by size.

- Ledgers: Safe load capacities vary; for example, a 2.5 m ledger can hold a 1.71 kN/m central load or 2.70 kN/m uniformly.

- Adjustable Jacks: Made from 38 mm O.D. steel, adjustable over 45 cm, with varying load capacities by type.

- Cuplock Brace: Provides structural bracing.

Early Striking Technique: Formwork can be removed after 3-4 days while the structure supports curing concrete until it reaches sufficient strength.

CATALOG

Included Products

-

Cuplock System

WTD Steel Plank

Select options This product has multiple variants. The options may be chosen on the product page